Kansai Helios » News » A cool system revolutionizing e-mobility

A cool system revolutionizing e-mobility

E-mobility represents the forefront of innovation, where continuous improvements in efficiency and motor design pave the way for the future of transportation. At the heart of this evolution, we remain committed to analyzing market trends, engaging with stakeholders across the supply chain, and delivering ground-breaking solutions. Our latest product, EB 549 Pulse+, exemplifies this commitment and sets a new benchmark in motor design for e-mobility.

In recent years, more OEMs have embraced bonding varnishes for electric motor construction. Known for their high bonding strength, reduced motor noise, and superior corrosion protection, these varnishes eliminate the need for traditional methods like welding or interlocking. Thus, they streamline the production process and improve compatibility. Recognizing this shift, we developed EB 549 Pulse+ to address an emerging demand: media-tight stator stacks.

A new standard in motor efficiency

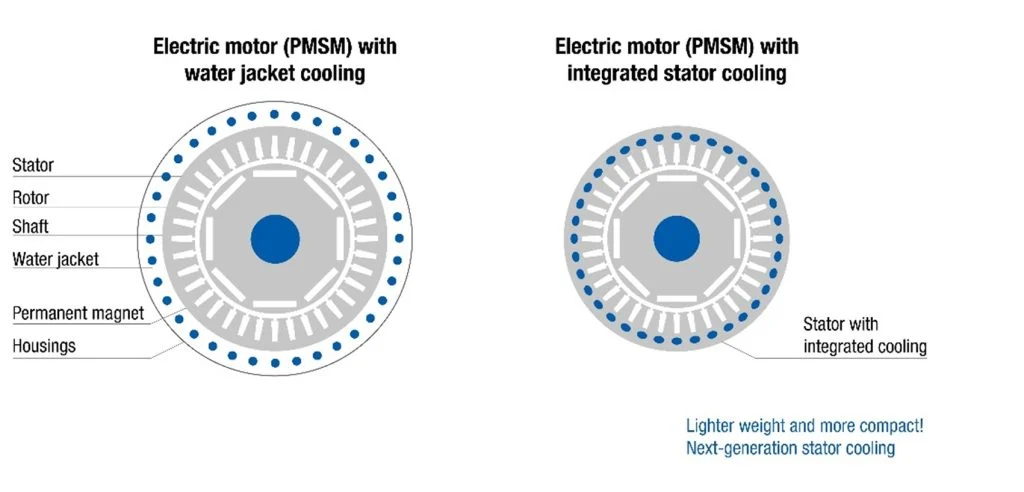

A motors performance and efficiency heavily depend on its thermal management. Traditional designs rely on external cooling jackets to dissipate heat, which can add weight and complexity to the motor. By integrating the cooling system directly into the stator, our new product offers a revolutionary approach. This innovation not only simplifies the overall design but also improves thermal conductivity, ensuring that heat is effectively managed even in high-performance applications. Moreover, integrated cooling systems reduce the number of components required, resulting in fewer potential points of failure. As a result, motors are more reliable, durable, and suited to the rigorous demands of e-mobility. Additionally, the improved thermal efficiency supports better energy conversion, contributing to the overall sustainability of electric vehicles.

COMPARISON OF EXTERNAL COOLING JACKETS AND INTEGRATED COOLING SYSTEM:

Developed for excellence and precision

EB 549 Pulse+ is already gaining traction. Steel mills regularly use this varnish, and its adoption is spreading as other manufacturers sample it for upcoming e-mobility projects. By integrating this innovative technology, OEMs, and their partners can achieve unprecedented levels of efficiency and design freedom. As market leader in core plate varnish, we know the challenges of the market and use our knowledge, experience, and innovation power to continuously develop our solutions. Our technical team provides comprehensive support to ensure the optimal application of this product, as the coating process requires precision. The top and bottom sides of the strip must be treated differently, with one side activated for the best results. Once the parameters are optimized, EB 549 Pulse+ delivers seamless performance and customer satisfaction.

This latest product launch enriching our Rembrandtin core plate varnish product range represents a significant milestone in our journey to redefine e-mobility. By introducing a varnish that enhances motor design, simplifies production, and improves efficiency, we are empowering the industry to embrace the future of sustainable transportation. Together with our partners, we are shaping a new era of innovation, one motor at a time.