Highest protection for all surfaces

Our liquid coatings protect your products from various degrees of stress in different environmental conditions. They ensure safety worldwide in the fields of renewable energy, ACE & truck trailers, railway, infrastructure, automotive, and the general industry. Here you´ll find a selection of advanced coating technologies, designed to meet the evolving needs of various industries. We support you in achieving the perfect balance between surface protection and design, as well as economical and ecological goals. Hybrid applications, seamlessly matching liquid coatings, powder coatings, e-coats, and other systems to provide you with the ideal solution, are our speciality.

High-solids (HS) and ultra-high-solids (UHS) coatings

HS and UHS coatings represent an ideal alternative to water-based products. Based on modern binder technologies these coatings for the general industry meet highest requirements in regard of corrosion protection, UV resistance, gloss and colour retention. They are particularly well suited for coating large surfaces such as rail vehicles or construction and agricultural equipment. By incorporating bio-based raw materials, we ensure that our coatings contribute to a more sustainable future without compromising performance.

Product Benefits:

- High corrosion protection

- Minimal VOC content

- Quick and effortless application

- Energy-efficient with low-temperature drying below 40°C

Dip coating solutions

Our dip coatings for radiators, motors, gears, axles, and ACE parts offer an exceptional corrosion protection for rough surfaces as well as outstanding resistance to cleaners and oils. Their streamlined application process makes dip coatings an efficient system for large objects. Dip coating offers excellent yield with minimal paint losses, making it an environmentally friendly choice for a variety of industrial applications.

Product Benefits:

- Exceptional corrosion protection for rough surfaces’ peaks

- Film thickness regulated by viscosity

- Efficient coating of large objects depending on tank size

Monolayers

Monolayer coating is a sustainable coating solution. Using a monolayer system can increase your productivity and decrease your energy and maintenance costs whithout any compromise in quality. The application process reduces logistical processes and, consequently, the carbon footprint of the coating process.

Product Benefits:

- Increased productivity from replacing primer and top coat

- Anti-corrosion protection for categories up to C4 according to ISO 12944

- Exceptional coverage of sharp edges (including those from laser cutting)

- High gloss levels (90%) and super-durable UV resistance available for selected products

- High-solid or water-based monolayer solutions

Wet-on-wet application

Wet-on-wet coating is a technique where two layers of paint are applied before the previous layers have fully cured. The entire coated surface then cures or dries as one composite layer. This method requires specially formulated coating solutions designed for this process. Both of the following options are energy-saving because only one curing cycle is required:

- Monolayer – a single application followed by one curing process

- Wet-on-wet – two applications with just one curing cycle

High temperature resistant coatings

Under senotherm® and Thermodur brands, we offer high-temperature coatings for stoves, ovens, flues, grills, and BBQ smokers. These products are renowned for their heat resistance up to 650°C and extensive colour options. They range from conventional systems to innovative, water-based options and ensure reliability, quality, durability, aesthetics, a pleasant touch and a good corrosion protection. Choose from standard classic coatings, Non-Smoker® solutions, or innovative water-based versions.

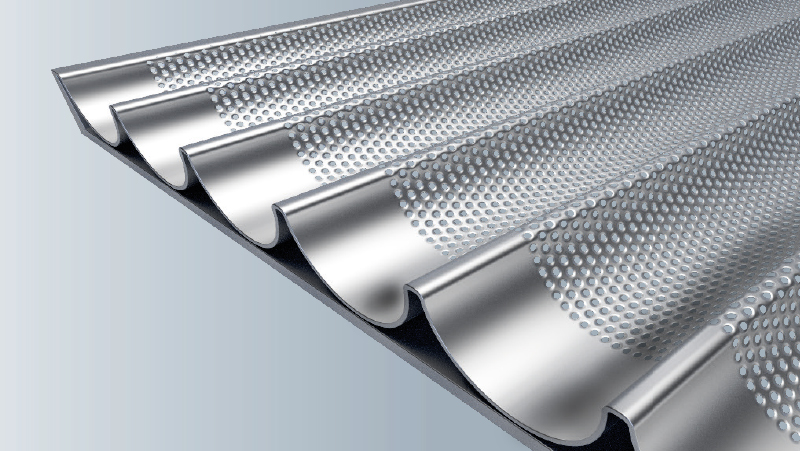

Coil coatings

Our coil coating solutions are an addition to our liquid coating portfolio. These coatings are designed to meet the highest demands of the coil coating process, offering superior protection and performance.

Environmentally friendly Sol-Gel Inks

Our sol gel inks for digital printing on coil are based on environmentally friendly solvents. They are durable coatings with excellent mechanical properties. Sol-gel printing inks are based on the same pigmentation as conventional coil coatings and therefore ensure good weather resistance. KANSAI HELIOS sol-gel printing inks are already applied successfully by various industries, including glass printing.

Core plate varnishes

Our core plate varnishes under the Rembrandtin brand are tailor-made for electrically insulating electrical steel, with a particular focus on environmental compatibility. All products are waterborne and entirely chromium-free. They adhere to the standards set by ASTM A 976-97 and IEC 6040-1-1, ensuring quality and compliance in insulating coatings by composition, relative insulating ability, and application.

Product Benefits:

- Excellent insulation capabilities

- Enhanced punchability

- Welding compatibility

- Resistant to annealing

Non-stick coating solutions

Under GREBLON® brand by WEILBURGER, we offer a wide range of non-stick solutions – a comprehensive assortment of precisely engineered coatings for industrial bakery or houseware applications. Whether based on fluoropolymers, silicones, or advanced sol-gel technology—and available in one-, two-, or even three-coat systems—GREBLON® delivers performance-driven solutions tailored to your needs. The GREBLON® Q-LINE is a PFAS-free non-stick coating solution.